If your swamp cooler is looking like it is being taken over by mineral deposits, well…that’s because it probably is. Swamp coolers aren’t something you can just plug in and forget about until the winter. Rather, you will need to do some periodic maintenance.

If your swamp cooler is looking like it is being taken over by mineral deposits, well…that’s because it probably is. Swamp coolers aren’t something you can just plug in and forget about until the winter. Rather, you will need to do some periodic maintenance.

Hard water certainly isn’t pleasant for swamp coolers. In fact, I know plenty of people who pipe soft water into their cooler. Really though, the cooler works off of evaporation, and what is left in the cooler is lots of salts. You can do several things to keep the environment inside the cooler operating as well as possible.

Most pumps have a bleed function that purges old water from the reservoir and pumps it out of the drain tube to the exterior of the unit. This will keep fresh water entering the unit at a low volume while getting rid of old water high in salts. You can run the tube outside, maybe to a garden, or somewhere you won’t just be wasting the water.

You can also buy water conditioning products which will help to keep the scale low. Most are blocks that you just set in the reservoir and it will slowly erode away.

If your pump does not have a bleed-off function, you can just periodically (every few days) empty the reservoir and refill it.

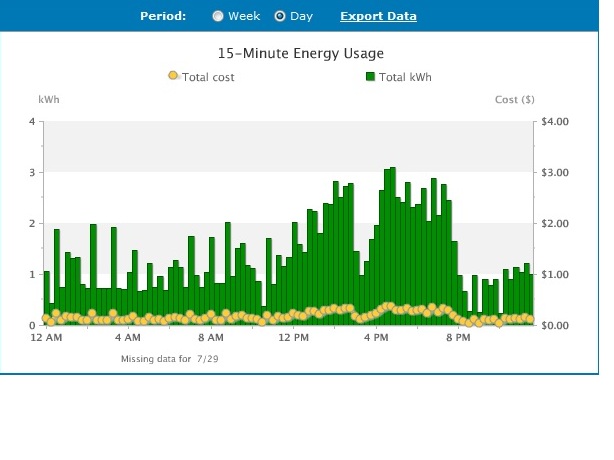

Although I’m not a big fan of my power company, they do provide me with some good information about my swamp cooler, and energy use in general. NV Energy has an online feature that allows you to get your actual energy costs in 15 minute increments. The information is very telling.

The picture above is my personal usage on hot, humid day in late July last year. I picked a day that was humid enough where I would not be able to use a swamp cooler and would have to use traditional air conditioning. This would allow me to see the actual costs of running the a/c.

To get my swamp cooler power costs, I used a Kill-a-watt meter and ran the cooler for several days. Some of the days were run on “low” and at other times on “high”. The "low" setting used .35 kWh (at $0.13 per kWh costs me $0.045 cents per hour to run), and at the “high” speed used .62 kWh to run (at $0.13 per kWh cost me $0.08 cents per hour to run). So depending on the speed, if I ran the swamp cooler 24 hours per day, my cost would be between $1.08-1.92 per day in electricity.

Shifting to air conditioning, if you look at the graph above, you can see spikes in the usage. These are times when the air conditioner turns on. The tall spikes between Noon and 8pm indicate times when both air conditioners are running simultaneously.

On this day, it looks like my baseline electricity usage is about .75 kWh every 15 minutes (way too high). When the air conditioners turn on, the kWh usage rises by approximately 2 kWh every 15 minutes (or about 8 kWh per hour!). At it’s peak usage, that would cost $1.04 PER HOUR for air conditioning only! According to the graph, that would be the maximum. I arrived at this my deducting the baseline amount from the peak usage.

The other day I was troubleshooting a swamp cooler because there were areas of the pads that were not getting wet. Then I pulled the sides off of the cooler and could see that water was intermittently coming from each tube from the spider at the top of the cooler.

The other day I was troubleshooting a swamp cooler because there were areas of the pads that were not getting wet. Then I pulled the sides off of the cooler and could see that water was intermittently coming from each tube from the spider at the top of the cooler.

At the bottom of the cooler is the pump, and it was much louder than normal. The pump sits in a basket that helps to keep debris from entering the pump and consequently the hose and spider. The drip tubes above the pads appeared to be taking turns flowing water onto the pads. There obviously wasn’t an obstruction, rather the pump was no longer pushing the volume of water up to the spider to distribute to the pads.

I disconnected the bracket that holds the pump to the housing and pulled up the pump to look at it. It was very crusty like something you would see from an old boat that had spent its entire life just sitting in water, less the barnacles of course.

Pumps are cheap, and so I bought a new one and installed it. It flowed plenty of water up to the spider and all drip tubes were flowing a consistent amount of water on top of the pads. Here is an article on how to replace a swamp cooler pump.

A swamp cooler spider isn’t normally the type of part that wears out or breaks. The spider is the assortment of tubes at the very top of the swamp cooler housing that distributes water to the various areas of the pads to keep them wet. It is called a spider because with the long tubes, it resembles a spider.

A swamp cooler spider isn’t normally the type of part that wears out or breaks. The spider is the assortment of tubes at the very top of the swamp cooler housing that distributes water to the various areas of the pads to keep them wet. It is called a spider because with the long tubes, it resembles a spider.

If you notice that an area of the pads is dry, check to see that you have a full flow of water coming from the spider. If not, you might try sticking a thin piece of firm but flexible wire through the end. It has to be flexible enough the make the 90-degree bend. The blockage will likely be near the end anyway, so just by picking at it you might get lucky and dislodge it. I have found picture-hanging wire works very well. If it bends too much, twist two strands of it together.

If you need to replace the spider, it is easy. Remove the screw that holds it to the top of the cooler. You will need to free each leg of the spider by slightly bending the metal holder and pulling the leg out. Once each leg is free you will need to pull the hose from the offset pipe that connects to the spider. By the way, the hose connects to the pump at the bottom of the cooler.

Once you have your new spider assembled, Screw the offset pipe into the bottom and push the hose back onto the barb. Screw the top of the spider back to the top of the cooler, and then install each leg back into the flexible metal holder. Turn the water on and you should have a good free flowing stream from each leg.

I got an email asking about why a swamp cooler would be smoking. Obviously, that is very concerning, and I would suggest you stop using the cooler until you can determine if there is a problem and what it may be.

I got an email asking about why a swamp cooler would be smoking. Obviously, that is very concerning, and I would suggest you stop using the cooler until you can determine if there is a problem and what it may be.

There aren’t many things in the cooler that would smoke. Certainly the motor, pump and the switch are connected to electricity, but if you are smelling smoke you need to investigate that carefully. With the volume of air being blown by the cooler, the smoke would have to be significant in order for you to smell it. It may not even be coming from the cooler. The swamp cooler blows outside air into the house. You can certainly smell a neighbor barbequing if the barbeque is close to your swamp cooler and the conditions are right. The same thing goes if someone is smoking near the cooler and the cooler is blowing a low volume of air. If you have a good sense of smell you can pick up these odors.

With that being said, there is water and electricity in the cooler, and when they mix bad things can happen. I would be cautious and investigate the cooler. It’s a matter of removing a panel and looking inside. If there is a problem inside, it should be pretty evident.

So what effect do you think shading and insulating a swamp cooler might have on its temperature? I suggest you do some testing yourself to see.

So what effect do you think shading and insulating a swamp cooler might have on its temperature? I suggest you do some testing yourself to see.

I have a side-draft metal swamp cooler that is roughly a 36” cube. Although I’ve done nothing scientific, I did a few things to see what changes might occur.

The cooler sits on the south side of the building in full view of the sun. There is a tall wall to the south of that, but with the sun higher in the sky in the summertime, it plays no role in shading the cooler. I keep a digital hygrometer connected to the front grill to monitor the temperature of the cooled air as it enters the interior of the building. At night the temperature of the cooled air will get down to 54-degrees (you don’t want to be standing in front of it without long sleeves). During the heat of the day, it is a different story. Of course, low humidity is the key to cold comfortable air in the building.

With the cooler off and the sun beating on it (the high temperature that day was 103), the hygrometer read 98 degrees at the mouth of the cooler. I set a piece of ¾” polyiso insulation board on the top of the cooler and 10 minutes later the meter read 88 degrees. Not bad. Realize that I was not running the cooler at this point.

I will be playing with getting temperature readings of shading and non-shading and posting them in the future. Just remember that if you are going to be shading your cooler, don’t block or restrict the areas where the air enters the cooler.

A Swamp cooler needs an occasional once-over. The biggest indicator is if the swamp cooler is not blowing cool air (assuming it’s not really humid outside). If the cooler is blowing air but it isn’t cold, that would suggest that the pads are not getting wet.

A Swamp cooler needs an occasional once-over. The biggest indicator is if the swamp cooler is not blowing cool air (assuming it’s not really humid outside). If the cooler is blowing air but it isn’t cold, that would suggest that the pads are not getting wet.

Remove a panel and take a look inside the cooler. Turn the pump on and make sure the spider is delivering water to the top of the pads. If the individual arms of the spider are working except one, you know the problem is isolated to that arm. Scale will sometimes get caught in the arms at a bend in the arm. You can probably dislodge it with a flexible pipe cleaner. Take your finger and first pick off any dried deposits on the end of the arm and then stick the pipe cleaner up there. You can do this while the water is running and hopefully when you dislodge the debris, the water will push it out of the arm.

If none of the arms are flowing water, check to see that the pump is working. If the pump works, you might consider removing the spider at the top of the cooler and investigating whether it is blocked. The spider is held on by a screw on top of the frame. You can disconnect the hose that runs from the pump to the spider and turn the water on. Water should shoot out of the hose. If water doesn’t come out of the hose, the problem is with the pump. If water does come out of the hose, the spider is plugged up and needs to be cleared out or just replaced.

If you use a swamp cooler, you are probably happy with the lower electrical bills. As I’ve said before, swamp coolers are simple machines, but you can’t just plug them in and forget about them. They will need occasional maintenance.

If you use a swamp cooler, you are probably happy with the lower electrical bills. As I’ve said before, swamp coolers are simple machines, but you can’t just plug them in and forget about them. They will need occasional maintenance.

So when do you know it’s time to replace the cooler pads? Well, that isn’t such an easy question to answer. If you see scale building up on the surface of the pads, it’s a good time to replace them. As water evaporates, what is left behind is the salts that accumulate in the water. You will see many water pumps that will have a bleed outlet to pump out a small amount of water while the pump is running. As water is slowly pumped out, the float drops to a level that allows fresh water to refill the basin. This minimizes the scale that builds up in the cooler (and will help your pads last all season). If you don’t have water in the basin automatically pumped out, you can remove the drain tube and manually drain out a few gallons of water every few days, or oven weekly. Over time you may notice that the temperature of the air may not be what is used to be. So go remove a panel and take a look inside. If your pads are covered in white scale and are hard as rocks, it may help to replace the pads.

For a swamp cooler to cool the air, it needs water. You can run water from a hose faucet (hose bib) to the cooler very easily. You can run either a copper water supply line or plastic and all the parts are readily available during the warm months.

For a swamp cooler to cool the air, it needs water. You can run water from a hose faucet (hose bib) to the cooler very easily. You can run either a copper water supply line or plastic and all the parts are readily available during the warm months.

You will need to buy a hose faucet with a swamp cooler adapter built into it. This is simply a threaded hole in the side of it so you can screw in a valve. So all that is left to do is to connect the water line from the hose bib to the swamp cooler.

Lay out the supply line (either copper or plastic) and connect one side to the hose bib valve. You will place the nut on first, and then a ferrule. Push those back enough so that you can insert a sleeve into the end of the line. Mate the insert up to the male end of the valve, push the ferrule up and tighten the nut. This will keep everything leak-free. If you do happen to see a drip, give the nut a quarter turn. Make the same connection at the swamp cooler. Turn the water on and you will hear the reservoir of the swamp cooler start to fill.

If your swamp cooler pads are not getting wet, you are going to have warm air blowing from your cooler. The problem is obvious: the water is not getting to the pads. So it is time to investigate why not.

If your swamp cooler pads are not getting wet, you are going to have warm air blowing from your cooler. The problem is obvious: the water is not getting to the pads. So it is time to investigate why not.

Let’s start with the easy things first. Make sure you have water in the bottom of your swamp cooler. This sounds stupid, but you would be surprised. I had a customer call us out for this exact reason…it turns out the landscaper turned off the water at the hose bib, which happened to be the one that supplied water to the swamp cooler. No water, no wet pads.

If you have water in the bottom of the swamp cooler, check to see that the pump is working. You should have a basket to keep out debris which could clog the impeller. You might remove the hose at the pump and turn the pump on to make sure water comes out of the outlet. If no water comes out, it may be time to replace the pump.

The last thing to check is the distribution to the pads. From the pump will be a larger tube that connects to an adapter at the top of the cooler. This adapter branches out into distribution tubes (called a spider) which go to the pads. If necessary, you can pull the tubes apart and clean them out. You can also use a pipe cleaner you might find at an arts & crafts store. Once you clean these out you should have water flowing to the pads.